Welcome to Our

State-of-the-Art Manufacturing Facility

A Hub of Innovation and Precision in Boiler Manufacturing

FACTORY FACILITY

Raw Material Storage Area (60,000 sq. ft)

Our raw material storage zone comprises three covered sheds for critical components and equipment, along with an open yard for structural, plate, and pipe materials. All materials are color-coded and systematically arranged to maintain proper inventory control. The organized layout ensures smooth logistics, easy accessibility, and operational efficiency, forming the foundation of our quality-driven manufacturing process.

Covered Shop Floor Area (60,000 sq. ft)

The core of our operations, this area is divided into seven manufacturing bays and two dedicated machining and tube-bending shops. All fabrication work is carried out here under strict quality control, ensuring precision, efficiency, and consistency in every product manufactured.

Semi-Closed / Open Manufacturing Area (2,50,000 sq. ft)

This expansive area is used for hydrotesting, packing, and final dispatch preparations. Its open layout allows us to handle large-scale fabrication jobs efficiently, providing flexibility and eliminating space constraints during project execution.

Blasting and Painting Shed (1,800 sq. ft)

A dedicated space equipped for shot blasting and high-quality painting, ensuring superior surface preparation and long-lasting protection for all fabricated components. This facility upholds our commitment to delivering products that meet the highest standards of finish and durability.

Factory Details

- 7 CLOSED BAYS

- 2 SEMI CLOSED BAYS

- 3 COVERED STORAGE AREAS

- 1 BLASTING AND PAINTING BAY

TECHNOLOGICALLY ADVANCED MACHINERY

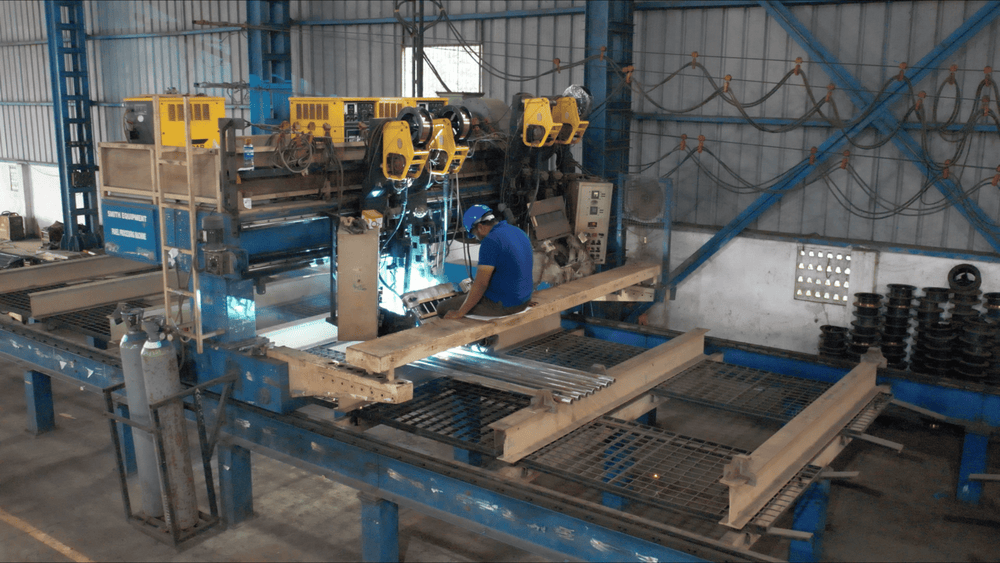

Gantry Type Four Torch Automatic Panel Welding Machine

High-productivity system for welding membrane wall panels with accuracy, ensuring consistent quality and finish.

100NCX & 65NCX 1D Booster Bending Machines (4 Nos)

Advanced bending machines capable of producing precise tube bends for boiler coils, minimizing Ovality and Thinning.

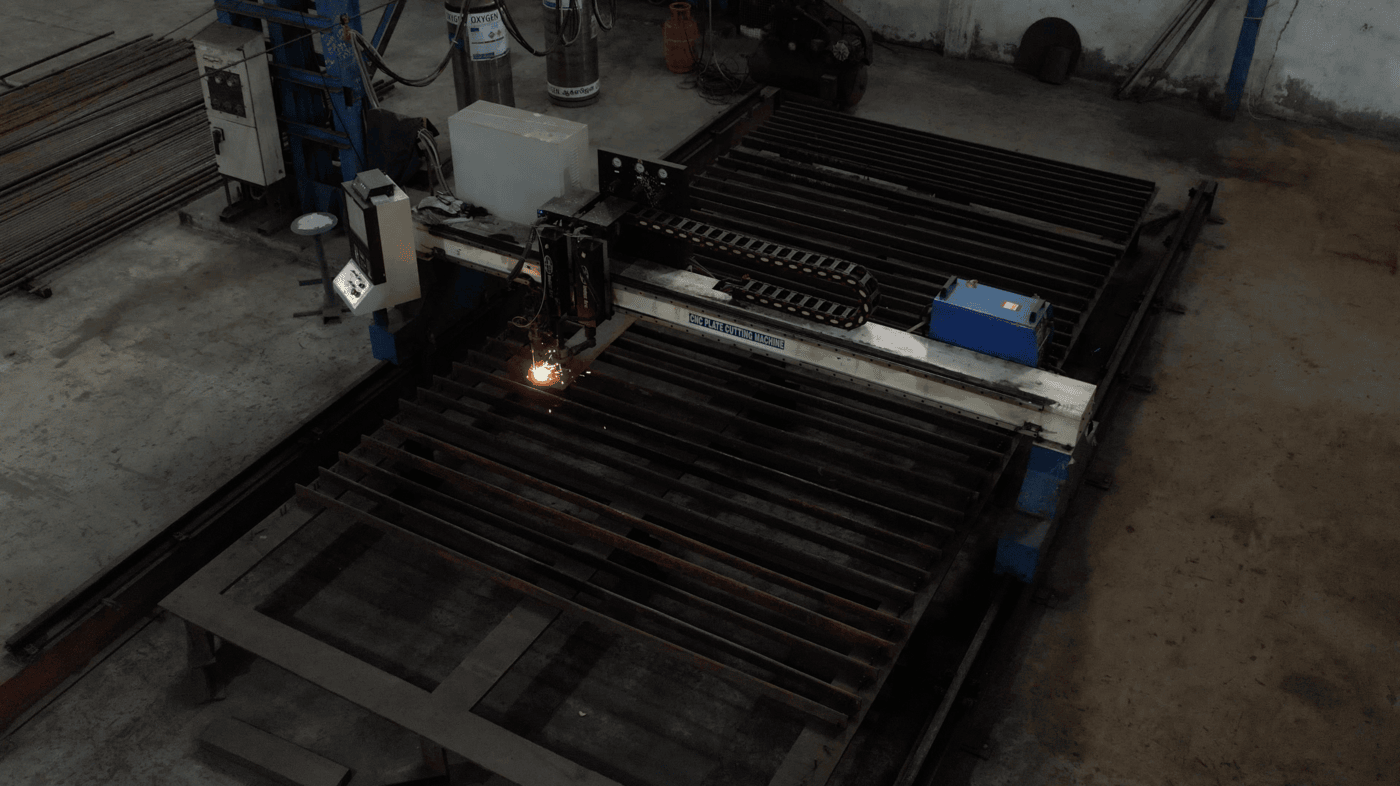

CNC Plasma cutting machine

SAW Automatic Welding Machines (2 Nos)

Submerged arc welding machines for deep penetration and flawless weld quality in critical boiler parts such as drums and pressure vessels.

Heavy-Duty Lathes (3 Nos)

Special-purpose lathes for machining long drums, shafts, and headers with exact tolerances.

RM-65 Drilling Machines (3 Nos)

Shearing Machine and Punching Machine

Accurate cutting of plates to required dimensions with clean finishes for further fabrication.

Studding Machine (2 Nos)

Specialized for welding studs onto boiler coils and panels, enhancing erosion resistance and extending service life.

PRODUCTION CAPACITY

Pressure Parts

300 Tonnes/Month

Non Pressure Parts

250 Tonnes/Month

Factory Location

Address

SF NO.373/3B, Kalamavur Village,

Kulathur Tk.,

Pudukottai district,

Tamil Nadu,

Pin: 622 502,

India.